THE IDEAL DISTRIBUTION CENTER STRUCTURE

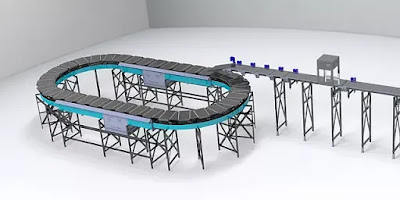

Flow: The distribution center stream can be abridged as the continuous development of materials, individuals, and traffic inside your structure. Your first objective ought to be to eliminate any regions of high traffic or potential for cross-stream crashes. In this way, every action that a representative performs must be situated as close as conceivable to the action that goes before it and continues from it. That additionally implies materials used to play out those exercises ought to be arranged as close as conceivable to every Warehouse Execution Software . Your subsequent objective ought to be to dispense with however much development and interruption as could be expected. Storage Planning: Regardless of whether you acquire some outside help or go only it, remember the accompanying tips when arranging your new distribution center format: Upgrade stream by limiting the number of contacts as SKUs go throu...